How it Works

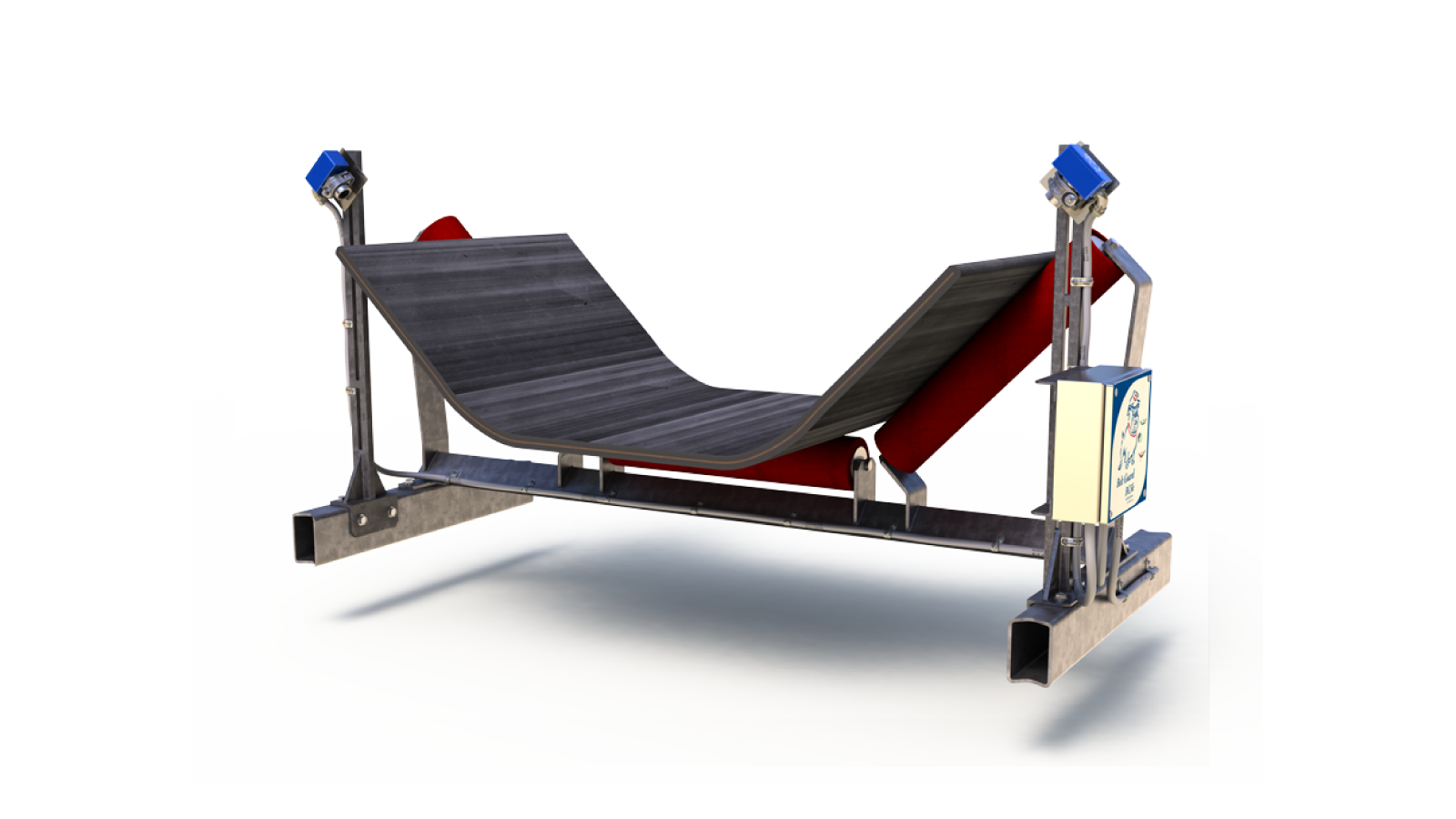

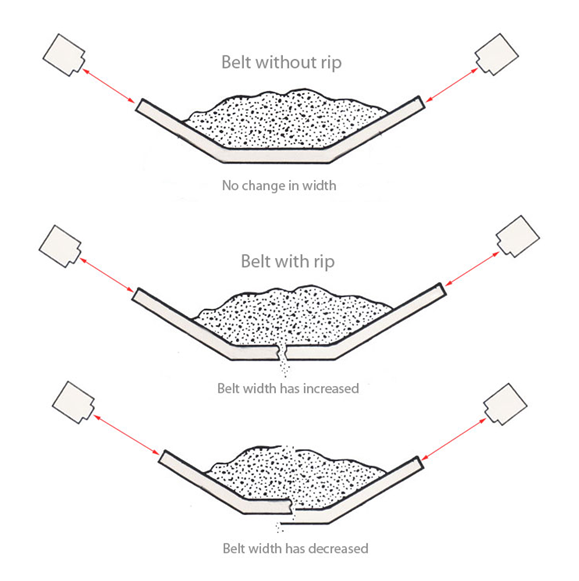

The Belt Guard BG5k provides a non-contact method of detecting a longitudinal rip in conveyor belting by monitoring the width of the belt, sensing a change in that width and operating a relay when a specified change in the width of the belt has occurred.

The relay may then be used to stop the belt by sending a HALT signal to the Conveyor's PLC and shutting the conveyor down.

Strategic location of a number of these devices may limit the length of a rip to within acceptable lengths.

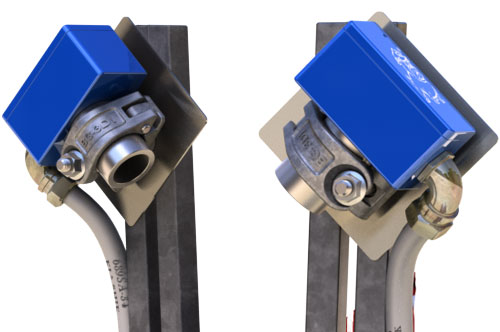

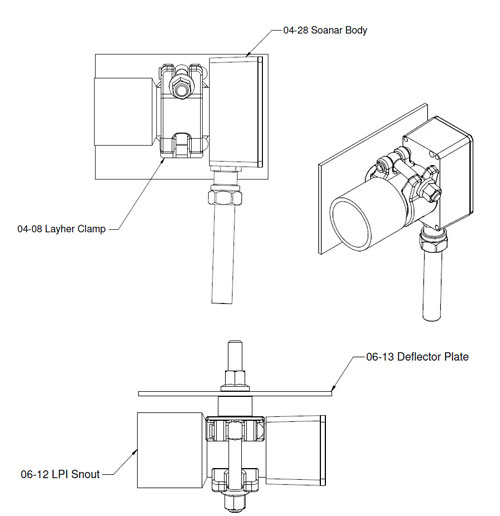

Non-contact monitoring of the belt width is achieved through the use of two Ultrasonic Probes, which are constantly sensing the belt edges.

When a longitudinal belt rip occurs, the torn sections of the belt commonly move away from each other, due to the product on the belt forcing the sections apart or the torn sections fold over each other and drop towards the bottom of the trough, due to the angle and centring forces of the wing idler rollers.

Should either of these two events take place, the width of the conveyor belt will change and a belt rip signal will be generated, which energizes the HALT RELAY.

Belt Tracking / Wander

An additional powerful feature of the BG5k is its Belt Tracking or Wander measurement capability. Tracking the lateral movement of the belt on its structure is vital, where product spillage is an issue. If a belt wander trend is detected early, remedial action can be taken to avoid product spillage.

The BG5k can sense lateral movements of less than a Millimeter and can provide alarms when certain thresholds are reached, allowing sites to change operating parameters in real-time to minimise the effect of belt wander.

Probes / Sensors

The Probes must be positioned on opposite sides of the belt and be adjusted to use the belt edges as targets. The distance from a Probe to the belt edge is the fundamental value driving the device and is recommended to be ~200mm, if this is considered a safe working distance for the target conveyor.

Each Probe is fitted with a product Deflector Plate to help minimise damage from spillage.

Communications

The Main Electrical Enclosure (MEE) connects the system to a Site's SCADA and Network (optional).

Technical support is provided via the Internet over Site's LAN (VPN or limited network access) or via a dedicated Mobile Broadband modem. This allows the device to be monitored remotely and software upgrades to be rolled out when available.

4-20mA outputs are also available, providing real-time belt lateral position information.

Installation

The device is simple to install and commission and these functions are normally performed by site personnel.

Most, but not all belt rips begin at a load point, where material is transferred onto the target conveyor. This implies that the Front End of the device (Probes) needs to be fitted after the last load point, where there are multiple product transfer locations, in any conveyor.

Maintenance

The BG5k equipment requires very little maintenance other than general housekeeping by ensuring the system is kept free from product build-up etc.

The sensors are self cleaning if left powered up but visual inspection should be carried out on a regular basis to confirm that product build-up will not become a problem. An alcohol wipe may be used for cleaning the Probe face.

Technical Specifications

| Application | |

| Belt Type | Fabric, PVC or Steel Cord |

| Belt Width | No Limit |

| Main Electrical Enclosure (MEE) | |

| Construction | 304 Grade Stainless Steel IP66 |

| Size (mm) | 370 x 230 x 370 (No Weather Shields) |

| Electronics | |

| Power Supply | 110/220 VAC 60/50Hz or 24VDC |

| Power | ~5W |

| Communications | TCP/IP Ethernet and PLC Control Cable |

| Operating Temperature | -13 ~ 158°F(-25 ~ 70°C), 5 to 95% RH |

| Storage Temperature | -40 ~ 176°F(-40 ~ 80°C), 5 to 95% RH |